Understanding Metasys BACnet Points

Learn to identify Inputs and Outputs, understand the differences between Hardware & Software points, and the characteristics of Binary, Analog, and Multistate points.

This is a post that I’ve been wanting to write for a very long time as I’ve seen over the years that there is a lot of confusion among building engineers, commissioning agents, and even experienced technicians when it comes to comprehending the functions and behaviors of various types of points in Metasys. At times, these points don’t behave as anticipated, making it challenging to adjust, override, or execute simple commands.

A Note Before Starting: I am explaining BACnet points in Metasys, specifically points coming from Johnson Controls controllers, not third party or other BACnet vendor devices as they can behave differently and create more confusion.

What is a Point

In Building Automation Systems (BAS), a “point” refers to an individual data element or parameter that the system or an operator can monitor, control, or manipulate. Think of points as individual pieces of information that represent various aspects of a building’s system, such as sensors measuring temperature, calculations processed by the BAS, or commands sent to actuators to open a heating valve. Points can also represent software entities such as equipment parameters, their operational status or a temperature setpoints to name a few.

These points form the foundation of BAS, enabling it to gather data, make decisions, and execute commands to optimize the building’s environment and operational efficiency.

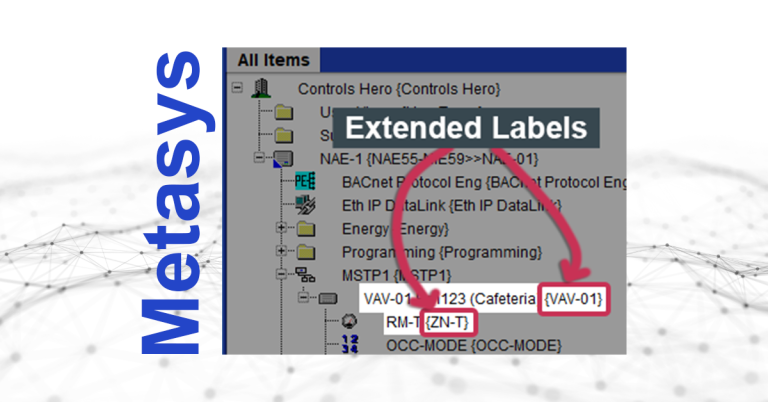

Metasys Points

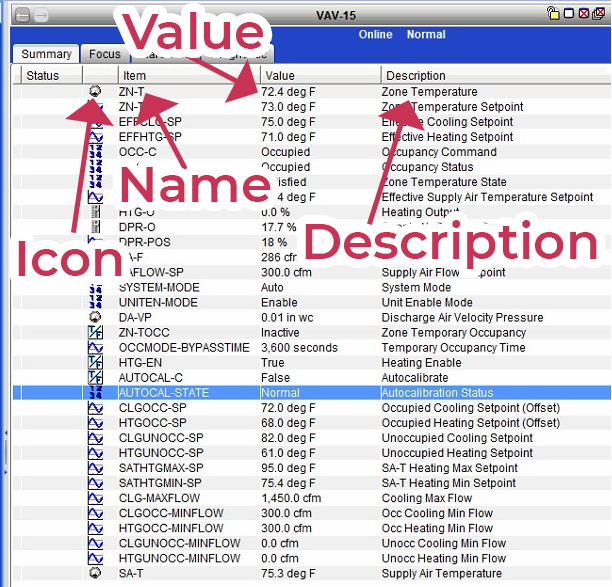

In Johnson Controls Metasys environment, points are represented by a unique icon, a name, a value, and an optional description. Each carrying valuable information about the nature of the point. Whether it’s an Input or an Output, a Binary or an Analog point, or even a Multistate point, and whether it falls under the category of Software or Hardware. Below is a snapshot of a Metasys screen showing various points for a VAV box.

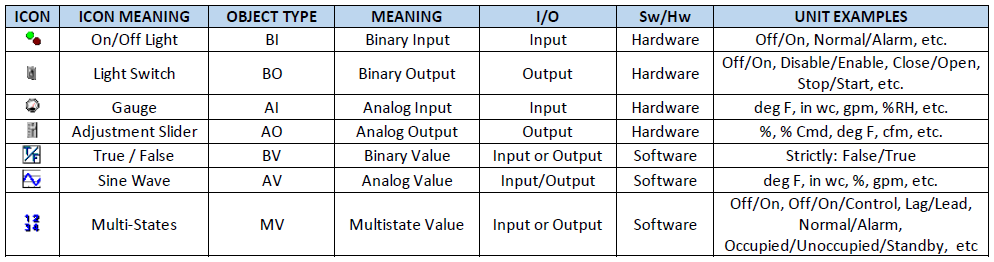

For your convenience, below is a summary table of the fundamental Metasys points discussed in this post.

Metasys – BACnet Points Summary Table

Before going in detail into each type of point (BI, BO, AI, AO, BV, AV & MV), it is imperative that you understand what is the difference between Hardware and Software points, as well as understanding Hardware Inputs vs Hardware Outputs with respect to a BAS controller.

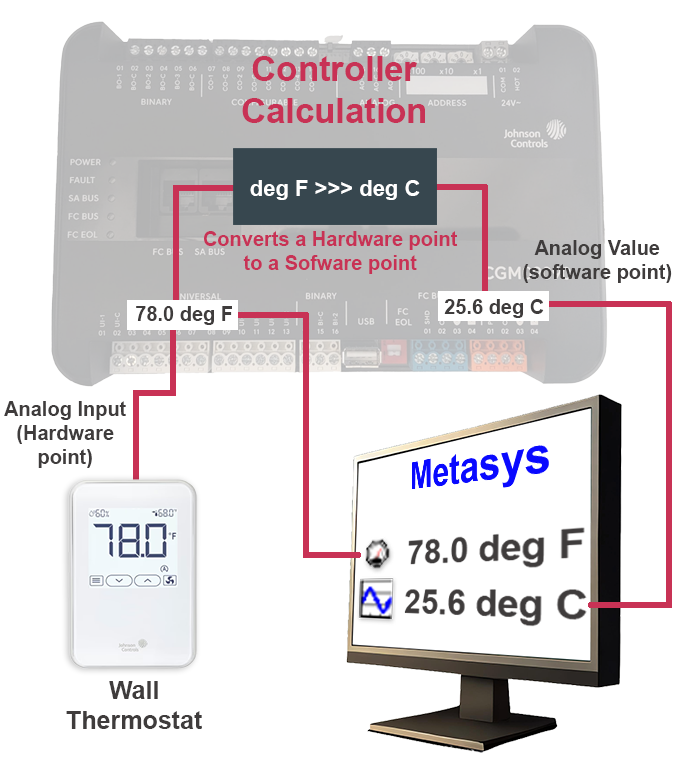

Hardware Points vs Software Points

In a BAS, Hardware Points refer to physical components that directly interact with the building’s systems. These can include sensors, meters, actuators, valves, and other tangible elements. Hardware points provide real-time data and facilitate direct control over the HVAC (Heating, Ventilation, and Air Conditioning) and other building systems.

Example

A quick note: In the Johnson Controls’ Controller Configuration Tool (CCT) some of the software points are called Network Inputs and Network Outputs. This is a discussion for another blog post!

What are Hardware Inputs and Hardware Outputs?

Hardware Inputs are wired signals received by the BAS controller from sensors, meters, actuators, Variable Frequency Drives (VFDs), and more. These devices can measure various parameters such as temperature, humidity, the occupancy of a room (motion), or can simply be a relay status showing that a fan is running.

Hardware Outputs in a Building Automation System (BAS) represent the commands or signals sent by the controller to devices such as actuators, valves, dampers, fans, and other equipment. These commands are crucial for the BAS to regulate and optimize the HVAC system based on the input data received. For instance, the controller may send commands to actuators to adjust the position of dampers for precise airflow control, or it could modulate a valve to regulate the flow of hot water through a heating system. Fans and pumps may receive commands from controllers outputs to vary their speeds according to a desired airflow or pressure.

The effectiveness of a BAS relies on these hardware inputs and outputs, as they directly influence the physical components of the HVAC system, ensuring it operates efficiently and maintains the desired environmental conditions within a building.

Now that we have reviewed what hardware points, software points, hardware inputs, and hardware outputs are, it will be easier to understand the most common Metasys points described below.

Metasys Hardware Points

We will start with the Metasys hardware points first, as they are the easiest to follow and understand. They are basically physical points wired directly to a BAS controller.

Binary Input (BI)

- Icon: Represented in Metasys by two LED lights (green = On, red = Off).

- Explanation: A point with only two possible states or values, that typically gives you the status of an HVAC system.

- Metasys Classification: A hardware point that is physically connected to one of the controller’s inputs. That is, a controller receiving a status signal from a device or a sensor.

- Examples of Values:

- Off/On

- No/Yes

- Close/Open

- Normal/Alarm

- Examples in BAS:

- A current Sensor Relay (CSR) indicating the status of a fan (Off or On).

- The position status of a control valve (either Closed or Open).

- A physical alarm status coming from a chiller control board (Normal or Alarm).

- Available Commands in Metasys:

- In Service

- Out of Service

- Temporary Out of Services

- Enable Alarms

- Disable Alarms

Binary Output (BO)

- Icon: Represented in Metasys by a classic light switch.

- Explanation: A point with two possible output states, typically used for controlling physical devices like lights, starting or stopping a pump, or opening a two-position damper.

- Metasys Classification: A hardware signal coming out from the controller’s physical output. It usually energizes a 24 VAC relay.

- Examples of Values:

- Off/On

- Stop/Start

- Close/Open

- Disable/Enable

- Examples in BAS:

- A BO can energize a relay in order to turn On a lighting system (Off or On).

- A command to start a water pump by closing contacts in a pump VFD (Stop/Start).

- It can drive an AHU’s isolation damper open (Close or Open).

- Available Commands in Metasys:

- Stop (it can be a different value such as Off)

- Start (it can be a different value such as On)

- Operator Override

- Temporary Override

- Release Operator Override

- Release

- Release All

- In Service

- Out of Service

- Enable Alarms

- Disable Alarms

Analog Input (AI)

- Icon: Represented in Metasys by an analog gauge.

- Explanation: A point that receives continuous data from physical sensors, providing a range of numeric values. Analog Inputs are commonly used for measurements such as temperature, pressure, or humidity.

- Metasys Classification: Hardware signal received by the controller’s physical input, in the form of a 0-10VDC signal, a 4-20mA signal or an RTD signal (Resistance Temperature Detector).

- Examples of Values:

- Temperature (22.3 deg C).

- Pressure (11.5 psi).

- Relative Humidity (34%RH).

- Examples in BAS:

- An RTD duct sensor measuring the temperature inside a duct.

- A static pressure sensor measuring the pressure in a duct.

- A flow meter measuring the water flow in a chilled water loop.

- Available Commands in Metasys:

- In Service

- Out of Service

- Temporary Out of Services

- Enable Alarms

- Disable Alarms

Analog Output (AO)

- Icon: Represented in Metasys by an adjustable slider.

- Explanation: A point that sends continuous signals to control devices, allowing for precise adjustments. Analog Outputs are used for modulating devices like valves, dampers, or the speed of a pump or variable fan.

- Metasys Classification: Hardware signal sent out from the controller’s physical output, in the form of a 0-10VDC signal, or a 4-20mA signal.

- Examples of Values:

- 0 %cmd to a 100 %cmd.

- 0 Hz to 60 Hz

- 45 deg F to 55 deg F.

- Examples in BAS:

- A 4-20mA signal going to a chiller card to adjusts its leaving temperature setpoint (e.g. from 45 to 55 degrees Fahrenheit).

- A 0-10VDC signal going to a VFD so it modulates the speed of a fan (e.g. from 15 Hz to 60 Hz).

- A 2-10VDC signal to control the position of a damper (e.g. 0 to 100% open) in an HVAC system.

- Available Commands in Metasys:

- Adjust

- Operator Override

- Temporary Override

- Release Operator Override

- Release

- Release All

- In Service

- Out of Service

- Enable Alarms

- Disable Alarms

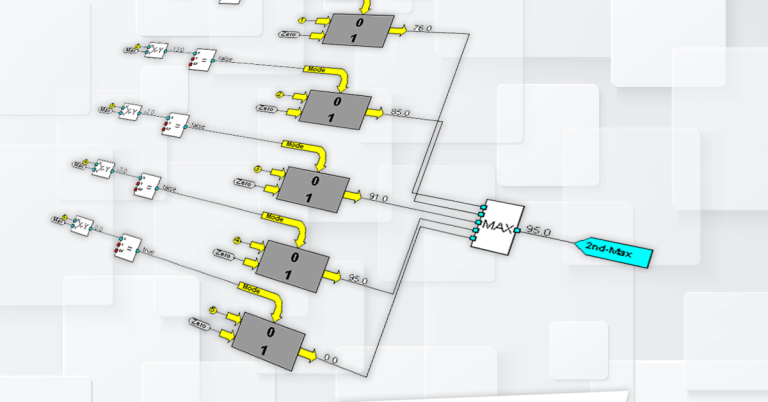

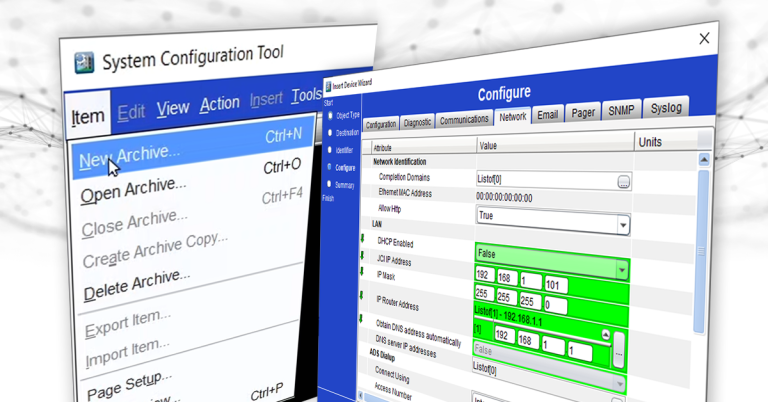

Metasys Software Points

Now, we will move on to Metasys Software points. To start off, these are not physical, they are “virtual” and they reside inside a controller application or inside a supervisory device (or Network Engine) such as an NAE or SNE. What makes these points very confusing is that they can behave as inputs or outputs, some of them can be adjustable and can be overridden, where others can’t (even if they have the same icon). Their behavior highly depend on how the point was configured by the controls technician or programmer.

Binary Value (BV)

- Icon: Represented in Metasys by a “T” and an “F” letter, indicating True or False.

- Explanation: A software point characterized by having only two possible states or values. Depending on its configuration, it can either be commanded, allowing user input, or serve solely as a status indicator without command functionality (non-commandable).

- Metasys Classification: A software or virtual point that resides either inside a controller application or in a Metasys supervisor (e.g. NAE or SNE).

- Examples of Values:

- Off/On

- No/Yes

- Close/Open

- Normal/Alarm

- Examples in BAS:

- Heating Enable point (HTG-EN) typically used in a VAV application. This point is commandable to True or False. It will allow the VAV box to go into heating when is set to True.

- A virtual status for a fan status. If a fan has a current sensor that reads amps when running, a programmer can create a BV to indicate “On” when the amperage reads above a certain value (e.g. above 1 amp).

- Available Commands in Metasys:

- When programmed as a fully commandable point:

- False (it can be a different value such as Off)

- True (it can be a different value such as On)

- Operator Override

- Temporary Override

- Release Operator Override

- Release

- Release All

- Change Default Value

- Enable Alarms

- Disable Alarms

- When programmed as a fully commandable point:

- When programmed as an adjustable-only point:

- Change Default Value

- Enable Alarms

- Disable Alarms

- When programmed as a “Status”:

- Change Default Value (You may send command it but it would not work)

- Enable Alarms

- Disable Alarms

Analog Value (AV)

- Icon: Represented in Metasys by a sinusoidal wave.

- Explanation: A software or virtual point that displays numeric values. Depending on its configuration, it can either be commanded, allowing user input, or serve solely as a numeric calculation without command functionality (non-commandable). These points are frequently employed for setting parameters, adjusting values, or simply serving as the result of a calculation.

- Metasys Classification: A software or virtual point that resides either inside a controller application or in a Metasys supervisor (e.g. NAE or SNE).

- Examples of Values:

- 55 deg F to 65 deg F.

- 0 to 1250 cfm

- 300 gpm.

- Examples in BAS:

- A Supply Air Temperature Setpoint (SA-TSET) for an Air Handler Unit.

- The air flow calculation of a VAV box (non-commandable).

- The flow setpoint for a chilled water system.

- Available Commands in Metasys:

- When programmed as a fully commandable point:

- Adjust

- Operator Override

- Temporary Override

- Release Operator Override

- Release

- Release All

- Change Default Value

- Enable Alarms

- Disable Alarms

- When programmed as an adjustable-only point:

- Change Default Value

- Enable Alarms

- Disable Alarms

- When programmed as a “Status”:

- Change Default Value (You may send command it but it would not work)

- Enable Alarms

- Disable Alarms

- When programmed as a fully commandable point:

Multistate Value (MV)

- Icon: Represented in Metasys by four digits: 1, 2, 3 & 4.

- Explanation: A software or virtual point with two or more possible states or values. Depending on its configuration, it can either be commanded, allowing user input, or serve solely as a status (non-commandable).

- Metasys Classification: A software or virtual point that resides either inside a controller application or in a Metasys supervisor (e.g. NAE or SNE).

- Examples of Values:

- Occupied / UnOccupied / Standby

- Off/On

- Cool Only / Heat Only / Fan Only / Water Flush / Purge / Auto

- Normal / Warmup / Cooldown / Coast

- Examples in BAS:

- The Occupancy Schedule point (OCC-SCHEDULE) in a VAV, that when commanded it, it can set the VAV into Occupied, UnOccupied, or Standby modes.

- In a VAV, the Effective Occupancy point (EFF-OCC), is a calculated point that tells you the occupancy status of the VAV, whether is Occupied, UnOccupied or in standby mode. It is not commandable as it behaves more like a status.

- In an AHU application, the Application Mode point (APP-MODE) is a commandable point that can set the AHU into the following modes: Cool Only, Heat Only, Fan Only, Water Flush, Purge, Vent, or Auto.

- Available Commands in Metasys:

- When programmed as a fully commandable point:

- Set Stage (e.g. Occupied, UnOccupied, or Standby)

- Operator Override

- Temporary Override

- Release Operator Override

- Release

- Release All

- Change Default Value

- Enable Alarms

- Disable Alarms

- When programmed as a fully commandable point:

- When programmed as an adjustable-only point:

- Change Default Value

- Enable Alarms

- Disable Alarms

- When programmed as a “Status”:

- Change Default Value (You may send a command it but it would not work)

- Enable Alarms

- Disable Alarms

Everything Makes Sense! So how can I get Confused?

All hardware points (BI, BO, AI & AO) are very straight forward when it comes to their functionality (as long as they come from JCI controllers), since they always behave the same way; as expected. The problem comes from software points (BV, AV & MV) since they depend on how the technician or programmer configured each point.

Here I share an example:

Unclear point names can create confusion such as the standard Supply Air Flow Setpoint in a JCI VAV application (an AV point). This point, when mapped, is called SAFLOW-SP. Since it’s named with the word “setpoint”, you may think it’s adjustable, but it’s not. Even if you try to command this point you will have the option to change its default value (as shown below) but it would not do anything. This point is actually the result of a calculation. It behaves like a status, it tells you the calculated flow setpoint that the VAV requires to meet in order to maintain the desired temperature setpoints.

Unfortunately, in many cases there is no easy way to understanding exactly how these software points work. In those cases you will need to have sufficient knowledge of Metasys and the Controller Configuration Tool (CCT). Below are some approaches to find out the behavior of a point:

If the points comes from a JCI controller:

- Consult the technician who programmed the point.

- Refer to the provided sequence of operation (SoO) from the controls company, seeking insights into the point’s functionality.

- Get a copy of the controller application (by doing an upload), and if you are familiar with the Controller Configuration Tool (CCT), you can analyze the point and figure out its behavior.

- You can send me a copy of this application and I can figure it out for you!

If the points resides in the SNE/NAE:

- Consult the technician who programmed the point.

- Refer to the provided sequence of operation (SoO) from the controls company, seeking insights into the point’s functionality.

- If you are familiar with the Metasys programming part, you can analyze the processes, interlocks, and/or logic and figure out its behavior.

- You can contact me and I can help you figure it out for you!

Conclusion

Understanding Metasys points is vital for building engineers, commissioning agents, and technicians to navigate the intricacies of the Metasys system. From Binary Inputs and Binary Outputs representing 2-state values, to Analog Inputs and Analog Outputs facilitating the reading of sensor data and making adjustments and overrides, to the software points BVs, AVs, and MVs, each point type serves a distinct purpose in monitoring, processing, and optimizing the building environment. The comprehension of their icons provides valuable information about each point. Ultimately, this understanding enables effective management and fine-tuning of building systems for optimal performance, energy efficiency, and occupant comfort.

If you have any questions or would like me to go more in deep about any of these point types feel free to leave a comment below. Thanks for taking the to read this loooong post…